It was a beautiful day for a rocket launch at the Dove Valley Regional Launch Facility. The temperature was a warm 80F which felt more like 95 in the bright sunshine from the cloudless sky. The winds were light to non-existent, making it perfect for those rockets with larger motors, of which we had a few.

I arrived shortly before 9:30 and noticed that the usually deserted park on a weekday had a steady stream of cars lined up to park, Ugh, Bronco training camp open day. I dutifully followed the directions, of the safety vest wearing attendant, and then circled around to my normal parking place close to the field. I also noticed that there were a couple of groundskeepers that were mowing the field, but figured that we could avoid them easily with our setup and flying. I did ask a worker there if the fields were being used today, and he responded that they were not being used and that he was “mapping” the field with a drone, flying a mowing pattern at 150 feet. I explained that we would be launching model rockets, and he said that we could hear the drone easily, and if we would not shoot him down, it would be fine. With that agreement, I proceeded to take the long walk to the right center of the field to set up my launch pad. I was greeted by a large swarm of gnats, so I moved the launch pad to where there were fewer of the little beasts in the calm still air. About that time David showed up carrying several of his rockets for the day.

After our greetings I had the first rocket of the day loaded up, a Jet Freak on a 1/2A6-2.

It was a nice straight launch, nosed over and dutifully ejected the engine. The glider started to settle into a slow turning glide, then suddenly nosed over and dove to the ground. No damage to the model, but it looks like it needs a little more tail weight.

Next up I loaded an Estes Gryphon, and Greg arrived to join our merry band of rocketeers. In the previous outing I had used a smaller motor, and the glider was nose heavy. This time it was loaded with an A3-4T, and I had balanced the glider to be slightly behind the balance point that Estes suggests, and I was rewarded with a beautiful flight. The rocket boosted nice and straight, the glider separated from the pod cleanly and settled into a nice slow glide turning in a wide left circle. It took its time to return to the ground.

David got into the act and launched his Estes Menace on a C6-5. It had a straight long boost and recovered a short walk from the pad.

By this time Greg had his pad setup and was ready to go with his beautiful Estes Low Boom SST on a C6-5 It flew a slow roll until burnout, nosed over and started a glide, then the parachute deployed and it was recovered not too far from the pads.

I had a Plastic Model Conversion (PMC) loaded on the pad next, a Pegasus model called the Apollo 17. With a name like that, it had to fly!

It was loaded with a D12-3, lots of nose weight, and a very small space for the 22” mylar parachute. Since the launch rod was not perfectly vertical, it boosted into a slow arc to the east, and the ejection charge fired about a third of the way back down. The parachute did not completely open, and it continued its path to just beyond the eastern side of the soccer fields. I had a bead on it and started walking towards the line of 4 newly planted trees that it had cleared, when I passed the trees, I noticed the D12 motor on the ground, well, there is a problem, but I am on the right path. About 10 feet further was a concrete path, that had no rocket on it, so I started scanning the un-mowed weeds and grasses beyond the path. Quickly I spotted an empty Doritos bag, and beyond that was the Apollo 17. The hard landing had broken one of the rocket pods off cleanly at the glue line. So, I picked up the pieces, ejected motor and Doritos bag and walked back to the launch pads. We all looked at it and decided that the parachute was just a bit too large for the space, and it was toasted slightly, which probably caused it not to open. This has promise, the pod is glued back on, and I will try again, maybe.

Following this was Greg with his Estes Super Orbital Transport on a D12-5.

He had flown it on our last outing to Dove Valley, and turned in a spectacular flight and glide. This time the launch was the same, but at apogee the rocket did not release the glider, so it rode the mothership and parachute back to the ground. Disappointing, but no damage done.

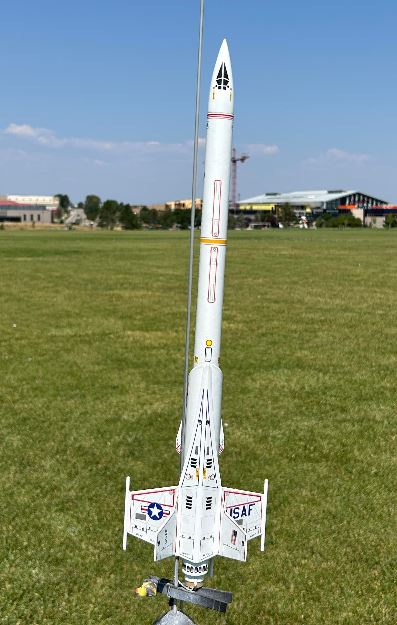

David had his old Quest X-15 model loaded and ready to go, this was a textbook flight on the classic model.

I followed this up with my slightly modified Estes DOM Nike Needle.

In the last outing the parachute was tangled and it came down fast and bent the body tube above the fins. I had rebuilt it since then and tried it this time on a B6-4, which was better than the previously used B4-4. It obtained a respectable altitude popped the parachute that fully filled, and floated gently to the ground. Next time it will get a C6-5.

Greg was ready next with his beautiful and fairly large Estes Navy Seahawk. The video was rolling and we had the countdown, 3, 2, 1… Dern it! Out to the pad to see what the problem was.

Once Greg had installed a new igniter and was back a safe distance, David then flew his NARAM special Estes Satellite Interceptor on a C6-5.

The Satellite interceptor took off with authority and deployed the parachute at apogee and slowly floated back down a short distance from where the pads were set up.

It was back to Greg and his Seahawk. This time the D12-5 in the Seahawk did the Navy proud and launched with the roar of the Mighty D motor to the skies, and then returned safely to earth under two fully inflated parachutes.

Next up I flew the Odd’l Rockets F-104, due to popular demand, well, David wanted to see it fly.

It was loaded with a B6-4 and leapt off the pad and set out the parachute nicely. On the way down I noticed that the nose cone was spinning around wildly, and wondered what the reason for that was. It turns out that the parachute did not completely open, causing it to spin, and the weighted nose cone helped it along. It landed and was returned with no damage other than a singed shock cord that will need to be replaced.

David was back at it again with his well-used Estes Photon Disruptor, on another C motor. It quickly gained altitude and recovered nicely under a fully inflated parachute.

About this time the mowing pattern of the mapping drone was coming close enough that we had to delay a couple larger launches, so I pulled out the Estes Twin Factor, loaded with A10’s for a low-and-slow launch.

The whole flight was easily seen, with the booster tumbling back and nearly hitting Greg, and the sustainer staging a little off vertical, and then nosing over and gently bouncing in the freshly mowed grass.

Now that the drone had moved away far enough, Greg had his large Nike Smoke ready to go loaded with an F15-4, which did not disappoint.

The Nike roared off of the pad to a fairly respectable altitude, and was returned under a perfect parachute.

Next, I loaded up the Space Case, Tri-Side Avenger. On our last outing it flew twice, did not deploy the streamer either time, and lawn darted. It had some damage that I repaired, and this time I would fly it on a B6-4. The Avenger boosted straight as an arrow, and we heard the pop, but it did not deploy the streamer. It started to fall horizontally, and as soon as David said, “that should minimize any damage”, it nosed over and performed its third, and final landing, a perfect lawn dart. Looking over the model, again the side was split along the seam, and the dowels that keep the nose cone on moved a short distance to vent the ejection charge, but not deploy the streamer. It is now a display model.

Greg followed this with a nicely built Estes Nike Apache.

The launch was straight on the C6-5, and deployed the parachute at apogee. The parachute was tangled and returned faster than expected, but it was recovered with no damage.

I followed that flight with the Sirius Rocketry Interrogator. David said that it was way prettier than his, which had several flights on it, to which I replied, “this has never flown”.

The Interrogator launched smartly on a B6-4, and floated down for a nice, David approved the flight. When I picked it up, the motor was hanging out of the back and held by the hook on the last inch of the motor.

During this, my friend Joe from work showed up to watch, and he was dutifully impressed with David’s “Go Army” rescued, rehabilitated, and repainted rocket launching on an Aerotech F15-3 Smoky.

The Go Army put on a fantastic show with a majestic smoky boost, and a full parachute return to earth, a beautiful flight.

Next on the pad was my Estes Astron Skydart II on a B6-2.

The Skydart managed a low but respectable boost, and then at apogee when it was horizontal, the ejection charge popped the pod out of the back and boosted the Skydart into a perfect loop, before it settled down into a nice slow circular glide with on the way down. It landed ready for another flight another day.

David then loaded his last flight of the day, a nicely built, first-generation, Rocketarium Jayhawk on a D12-5, and not the recommended D12-3, because David said that it would have a “longer glide” that way. He was correct, the Jayhawk boosted nicely, nosed over and settled into a gliding dive, until the ejection charge went off and it floated back under its parachute for another safe recovery.

Next, I set up the Estes QCC Explorer, that had been modified with a baffle and zipperless deployment. The QCC Explorer was loaded with D12-5. The Exploder roared off of the pad, straight up into the air, deployed the parachute and floated gently back for another perfect flight of the day.

Greg launched his final rocket of the day, the nicely painted Estes Black Brant III.

The Black Brant, loaded with a B6-4, and had a beautiful paint job, flew up with a distinctive corkscrew smoke trail, much to Gregs astonishment, and the amusement of the rest of us. On the previous outing it had launched straight as an arrow, so that ruled out mis-aligned fins when he launched it. Once it was recovered the corkscrew investigation began. The leading theory is that while it was laying in the grass for over an hour waiting to launch, the side pointing at the sun expanded slightly, giving the body tube a small curve, which caused the interesting flight. This then led to an interesting conversation about rotating our rockets while they wait for launch, or building a rotisserie to turn them for us, which I am sure that we all will forget before our next outing.

The final flight of the day was my Estes Astron Explorer on a D12-3.

The Astron Explorer leapt skyward and left a nice straight smoke trail, then its luck ran out, we could see that it was now backsliding down trailing a parachute that was not inflating. The Astron explorer was in a stable one fin down glide when it ran into the soft ground, embedded the lower fin about 2” into that ground, and then allowed the rest of the rocket to continue, separating rather cleanly on the glue line for that fin. There is a minor crease on the body tube at that location, and there were four shroud lines that were ripped off of the parachute, causing it to stream behind the rocket on the way down.

After this less than stellar final flight, we struck the range and headed to Arby’s for a reprieve from the heat and sun in the air-conditioned environment. We had a nice lunch, and great conversation for another hour or so until we left the restaurant to each head home until another launch would bring us back together.

Blogger's note:

Many thanks to Mike Goss for organizing this launch, drafting the report write-up, and providing some awesome pictures. Thanks also to Greg Hauser for editing the report.

Cheers!