This part of the build focuses on building up the motor mounts for each of the selected model rockets.

Here is a group pic of all the completed mounts:

Mounts that use the (flimsy) paper rings have been reinforced with balsa support vanes to prevent them from flexing under thrust forces.

For the BT-60 sized birds (Big Bertha and Esam-58), I went with some longer BT-20 stuffer tubes.

One further modification to the Big Daddy mount involves building the motor tube to accommodate the longer E- motors.

For a couple of these mounts, I didn't have enough centering rings in my parts stash, so I cut some out of 1/16 basswood.

Additionally, a lack of enough stock engine hooks meant that I had to fashion a couple out of old windshield wiper springs.

Sometime in the recent past, I must have raided the kit pile to purloin some of these parts for other scratch-built models.

Oops, yet another motor mount modification:

It seems that, at some point in time, I lost the inner motor retainer ring that came with the ESAM-58 kit. So, this mount gets the normal motor hook, instead.

"Hey, BlastFromThePast, you said you were starting six new kits. How come the photo shows seven motor mounts?"

Very astute observation.

The short answer: I am modifying the Quest Icarus build considerably. The shorter 35mm tube, instead of being a payload section, is being built as a 24mm motor booster stage. The Icarus will share the Big Rage's payload section with that model. Awhile back, I lost the Big Rage "Nike Smoke" nose cone, and ended up stealing the nose from the Icarus kit to replace it.

Confused? Me, too...

In the near future, I intend to send off an order to Quest that will include a new Nike Smoke nose cone and a 35mm tube, so I can straighten out the mess and restore both birds to their original form.

For the Icarus booster, I had intended to cut centering rings out of basswood, but I have since discovered that an Estes BT -55 fits snugly inside of the Icarus' 35mm tube. I can now make the components by gluing Estes 50-55 rings into short lengths of BT-55. A very convenient and time-saving work-around.

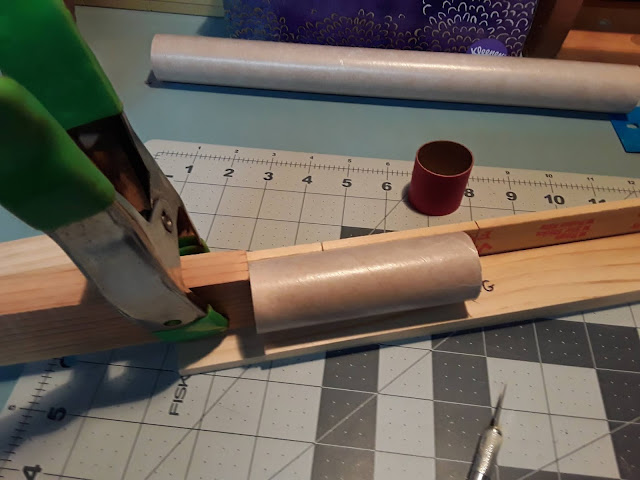

Here is the tube-cutting process I use:

A shop-built "Kuhn Cutter" made from some Home Depot paint stir sticks makes for some precision cuts for the two centering ring BT-55 extensions. This particular tube came from a Cherokee-E kit in damaged condition, so it's perfect for cutting up into shorter useful parts.

This is the finished motor mount, now ready to plug into the Icarus booster.

Next step: Gluing 'em all into the airframes.

More to come...