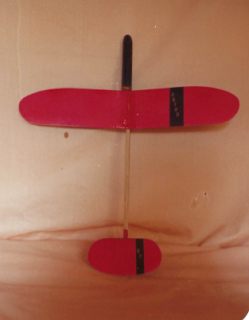

My return to the hobby of space modeling as a 'Born Again Rocketeer' has abruptly whisked me off into the realm of front engine boost and rocket gliders. I knew it would only be a matter of time before I was once again diving into what was undoubtedly my most favorite facet of model rocketry in the earlier days.

That being the case, it is now imperative that I build an appropriate ground support system to accommodate these interesting models. And, having allotted myself a limited amount of monetary resources for model rocketry, this system must be built on the cheap!

There are two major criteria for building a good launch system for front engine gliders:

Launch rod length, and preventing clip lead hang-ups.

The Launch Rod

Many rocketeers (myself included) have made the mistake of using a standard 36-inch launch rod to provide initial guidance for their front engine B/Gs. The problem here is that the length of the glider requires that the engine pod be placed higher on the rod. This results in only 18-24 inches of effective rod length remaining to guide the model. Usually, a glider model hasn’t reached sufficient airspeed over this short distance to continue in a vertical ballistic trajectory. In most cases, the model will leave the rod and ‘tip off’ in any direction, resulting in a near horizontal or spiraling flight path, sacrificing altitude. In the worst case, the model is quite prone to attempting to enter a region of extremely high drag (the ground) under power.

“No good!” says BlastFromThePast.

There are two effective methods for achieving proper launch rod length for B/Gs and R/Gs. The first is to simply build an extension of the launcher, such as a wood dowel or a metal bar where the launch rod can be inserted into the end.

The other method is to simply get a longer launch rod.

That is my choice for the new launcher, so a trip to the BORG (that’s Big Orange Retail Giant a.k.a. Home Depot) to pick up a 1/8” x 48” rod, was in order. I was quite surprised to find that it took a little bit of searching through the available stock to find a perfectly straight rod.

Chinesium. Harumph!

Now, with a standoff, I can place most any B/G model on the rod and have enough length to properly guide the model.

But, what about the second point?

The Clip Leads

Merely hanging some unsupported clip leads from the engine pod introduces the risk of having them fall and hang up on the glider at ignition.

The solution – build a gantry to hold the leads and allow them to swing AWAY from the glider after having performed their assigned task.

My version of this device is engineered quite simply, using a couple scraps of wood and a small assortment of hardware.

First, a base is cut from a small 1x3 block of hard maple. A 1/8” diameter hole is drilled in the center to allow the base to fit snugly over the launch rod.

Normally, I would perform this function the ‘Neanderthal’ way, using an old timey ‘eggbeater’ hand drill. But, since I need this hole to be exactly perpendicular to the rod, I had to fire up the drill press for better accuracy.

Next, a 12” stick of ½” square pine is scrounged out of the wood scrap box. This will make a dandy gantry.

To mount the gantry to the base, I will be using a common small angle bracket. Since I want the gantry to lean slightly away from the launch rod, the bracket gets squished between some vise jaws to bend it at to approximately 110 degrees.

To hold the clip leads, a hook is made from a short length of clothes hanger wire. This will be inserted into a hole at the top of the gantry.

I told you this project would be cheap and simple…

Before final assembly., the wood pieces are sanded smooth and painted to look more ‘purty’.

All the parts are now attached using small flat head screws.

The clip hook is inserted into a hole drilled at the top end of the gantry...

Voila! A cheap, yet efficient launcher accessory.

Nothing fancy. Nothing schmancy. Cost me all of a few cents and an hour to build.

Now it’s off to fly me some Boost/Gilders!